Introduction

Thermal linear expansion is a source of uncertainty that you need to consider if you perform dimensional and mechanical tests or calibrations.

Typically, it affects measurement results that involve length or displacement. However, it can also affect measurement results in the following categories:

- Pressure

- Torque

- Flow

- Volume

- Area

When evaluating thermal expansion, most people know to find the coefficient of thermal linear expansion. However, many people have trouble applying it to their measurement results.

So, I decided to create a guide to teach you everything that you need to know about thermal linear expansion and how it affects your measurement results.

In this guide, you will learn:

- What is Thermal Linear Expansion

- Why Thermal Linear Expansion is Important

- When to Include Thermal Expansion in Your Budgets

- How to Reduce Thermal Expansion

- Thermal Linear Expansion Formula

- How to Calculate Thermal Linear Expansion (step by step)

- Examples of Thermal Linear Expansion

Click here to download the thermal expansion calculator for free!

What is Thermal Linear Expansion

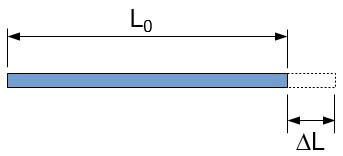

According to The Engineering ToolBox, when an object is heated or cooled, its length changes by an amount proportional to the original length and the change in temperature.

According to Merriam-Webster, thermal expansion is the increase in linear dimensions of a solid or in the volume of a fluid because of change in temperature.

Therefore, it is the change in the dimensional properties of an object when exposed to changes in temperature.

If you perform dimensional and mechanical testing or calibration, you may want to consider thermal expansion when estimating measurement uncertainty. Most likely, it affects your measurement results and should be included in your uncertainty budget.

Why is Thermal Expansion Important

Thermal expansion is important because it can affect your measurement results. Furthermore, it can affect the quality of your customer’s measurement results.

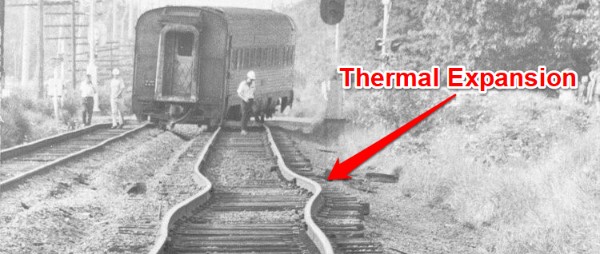

In a world where tighter tolerances are in demand, thermal expansion errors could have a significant effect on meeting specifications.

When you neglect to consider its effects, you provide your customers with bad measurement results that could affect the quality of their products and services. Additionally, disregarding these errors can increase your risk of encountering a false-accept or false-reject in your conformance statements.

Depending on your customer’s business activities, bad measurement results could increase their risk of problems, damages, and unplanned downtime. Even worse, it could impact the health and safety of people.

According to a recent study by Vanson Bourne, 23% of all unplanned downtime in manufacturing is the result of human error.

It can affect the following measurements:

- Pressure (changes in volume and area)

- Torque (changes in radius)

- Flow (changes in volume and area)

- Speed/Velocity (changes in length/distance)

- Energy (changes in length/distance)

- Volume (changes in length, width, and height)

- Area (changes in length and width)

When to include Thermal Expansion In Your Uncertainty Budget

You should include thermal expansion in your uncertainty budgets when:

- its effect is considered to be significant, or

- the measurement result is not corrected for it.

Typically, thermal linear expansion uncertainty affects dimensional and mechanical measurement systems. However, it is not always considered in the uncertainty budget.

If thermal expansion contributes to five-percent (5%) or more of the total uncertainty, then it is considered to be significant and should be included in your uncertainty budget.

If the effect is estimated to be less than 5%, then it can be omitted from your budgets.

If you take expansion into account when performing tests or calibrations, then you can omit it from your uncertainty budget. If you do not correct for it at the time of test or calibration, then I recommend that you include it in your uncertainty analysis.

However, I always recommend including common sources of uncertainty in your budget even if you give it a value of zero. Just make sure to include notes explaining why it was or was not considered in the analysis. This will help you and assessors understand your uncertainty budgets.

How to Reduce Thermal Expansion

There are several ways to reduce the effect of thermal expansion. You can try to:

- Reduce contact with/exposure to heat sources,

- Control the environment,

- Allow thermal stabilization, and/or

- Correct for thermal expansion

Making contact with an item can transfer your body heat to the item causing thermal expansion. Additionally, placing an item next to a heat source, heat sink, or cooling source can change the item’s temperature causing expansion or contraction.

If you can reduce contact with or exposure to heat sources, you can reduce the effect of thermal expansion.

Try to avoid:

- Body heat,

- Equipment that generates heat,

- Windows,

- Sunlight,

- HVAC vents, and

- Objects with a different temperature

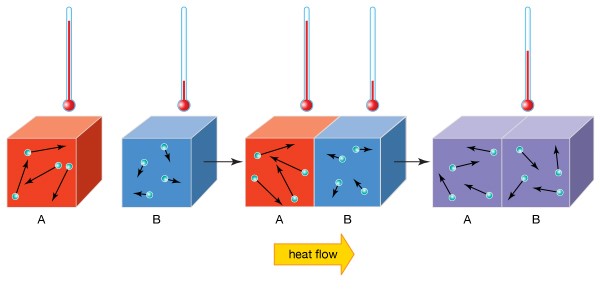

In the image below, you see two objects with different temperatures make contact. Heat flows from the warmer object to the cooler object (1st Law of Thermodynamics) until they reach thermal equilibrium. The larger the temperature difference, the greater the rate of heat flow.

To reduce thermal expansion effects, avoid making contact with objects that have different temperatures.

Another way to reduce thermal effects is to control the environment. A well-conditioned environment will reduce heat transfer and help an item maintain a stable temperature which will reduce thermal expansion.

Furthermore, you can minimize thermal effects by allowing an item to thermally stabilize in the environment it will be tested or calibrated. If you allow the item to achieve thermal equilibrium with the environment, it will reduce the effects of thermal expansion.

Finally, you can always correct for thermally induced errors to minimize the effect on your measurement results. Make sure that you monitor the item’s temperature, not just the temperature of the environment. Air temperature is subject to change faster than an item’s temperature. So, monitor the item’s temperature or take into consideration the material’s rate of thermal conduction to estimate thermal effects due to changes in air temperature.

See How We Can Help Your Lab Get ISO/IEC 17025:2017 Accredited

- Uncertainty Budgets – let us estimate uncertainty for you.

- Custom QMS – we’ll create your quality manual, procedures, lists, and forms.

- Training – get online training that teaches you how to estimate uncertainty.

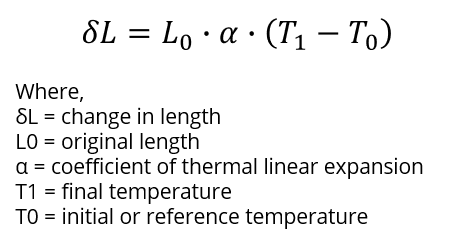

Thermal Linear Expansion Formula

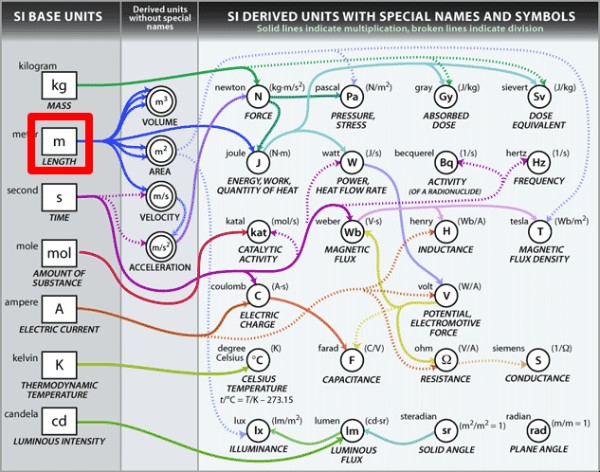

Calculating the effects of thermal linear expansion is not hard. There are only few variables that you need to know to perform the calculation. These factors are:

- Original length,

- Coefficient of linear thermal expansion,

- Initial temperature, and

- Final temperature

It is not always easy to find the exact thermal expansion coefficient associated with the material that you are evaluating. The best recommendation that I can give you is to contact the manufacturer of the item you are evaluating to find the actual material composition and expansion coefficient.

Otherwise, you may have to look up a reference table to find the closest value.

Use the formula provided below to calculate thermal linear expansion. The result can be used to estimate the thermal effects on measurement uncertainty.

How to Calculate Thermal Linear Expansion

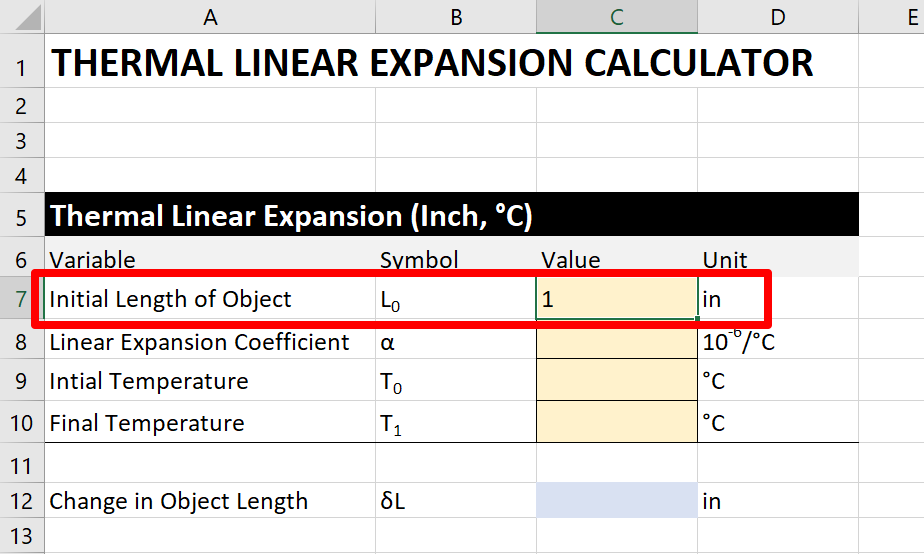

Follow the instructions below to calculate thermal linear expansion using the formula in the previous section.

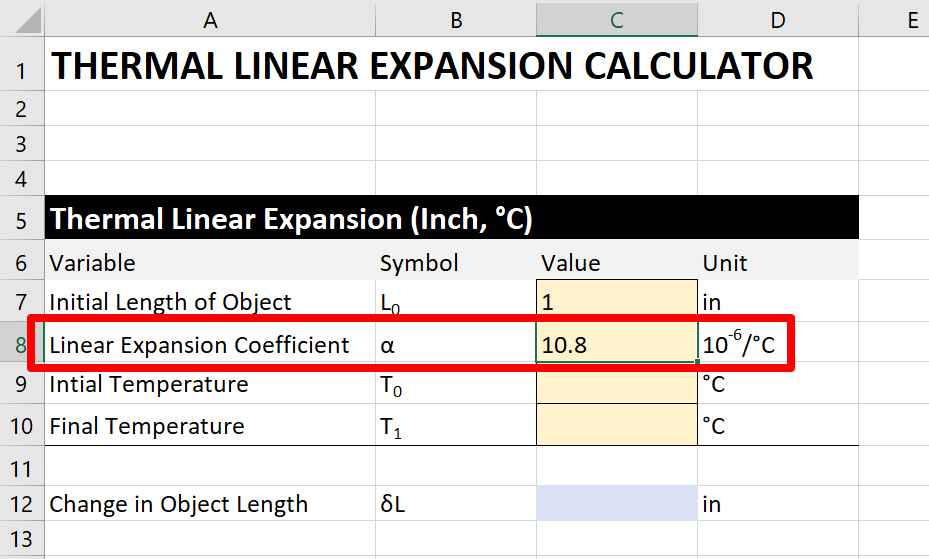

Step 1. Find the original length of the object

For this process, let’s estimate the thermal linear expansion of a 1 inch gauge block.

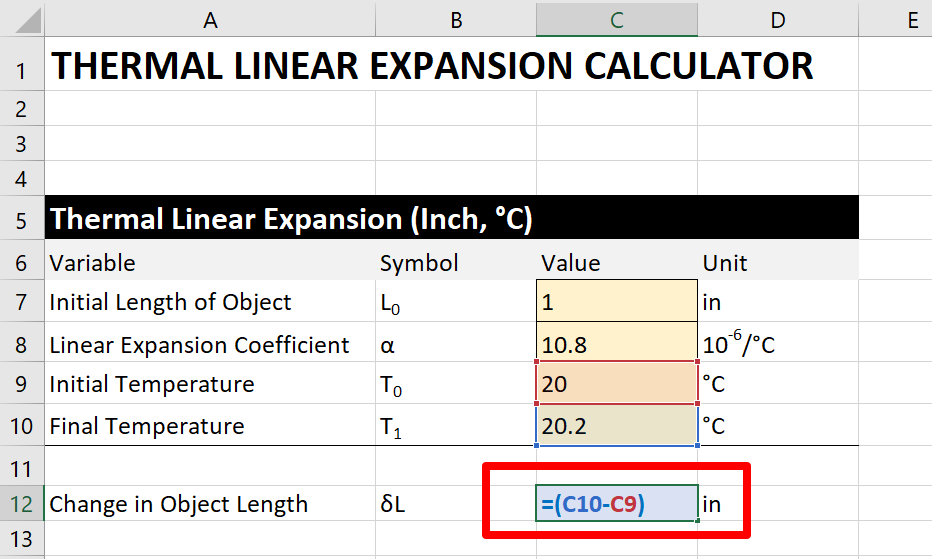

If you download the calculator associated with this guide, enter the original length of the object. Use the image below for guidance.

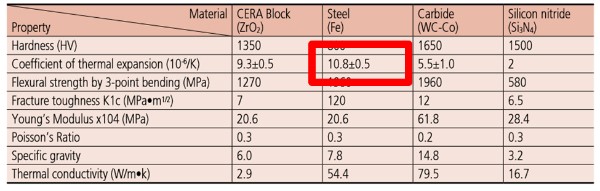

Step 2. Find the coefficient of thermal linear expansion

Refer to manufacturer published specifications to find the coefficient of thermal linear expansion. If you cannot find it, try using a reference table to get an approximate value.

Then, enter the coefficient of thermal linear expansion into the calculator. Use the image below for guidance.

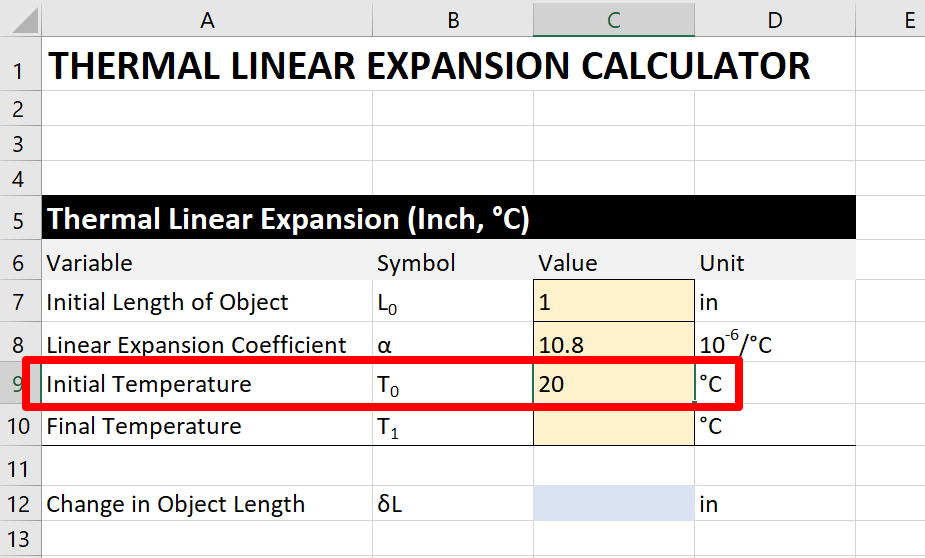

Step 3. Find the initial temperature

Now, monitor and record the objects temperature before you begin testing or calibration. This will be the initial temperature.

Then, enter the initial temperature into the calculator. Use the image below for guidance.

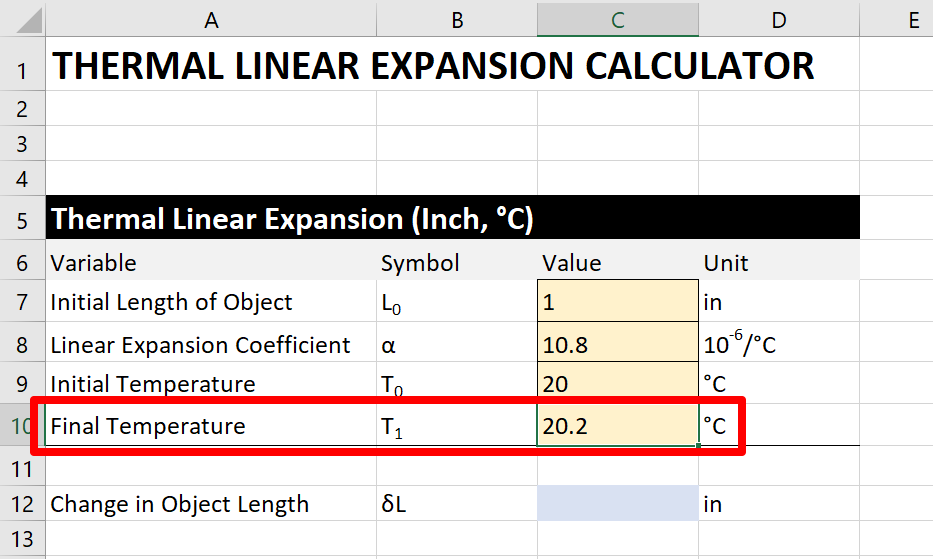

Step 4. Find the final temperature

After you have completed your test or calibration, record the final temperature. Then, enter the final temperature into the calculator. Use the image below for guidance.

Step 5. Calculate the change in length

Next, calculate the thermal linear expansion using the formula in the previous section. To make the task easier, I have broken down the process according to the order of mathematical operations.

5a. Calculate the change in temperature

To calculate the change in temperature, subtract the final temperature by the initial temperature.

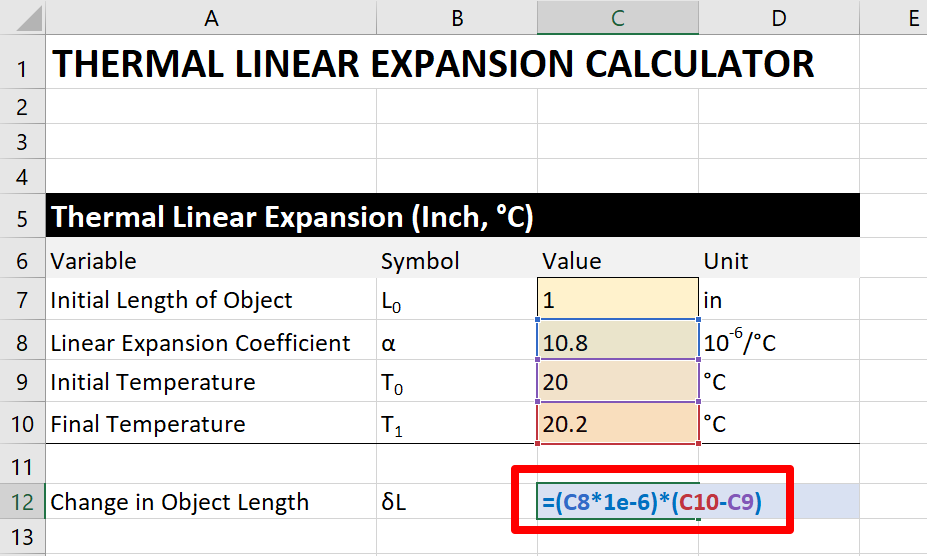

5b. Multiply by the coefficient of thermal linear expansion

Next, multiply the result from step 5a by the coefficient of thermal linear expansion.

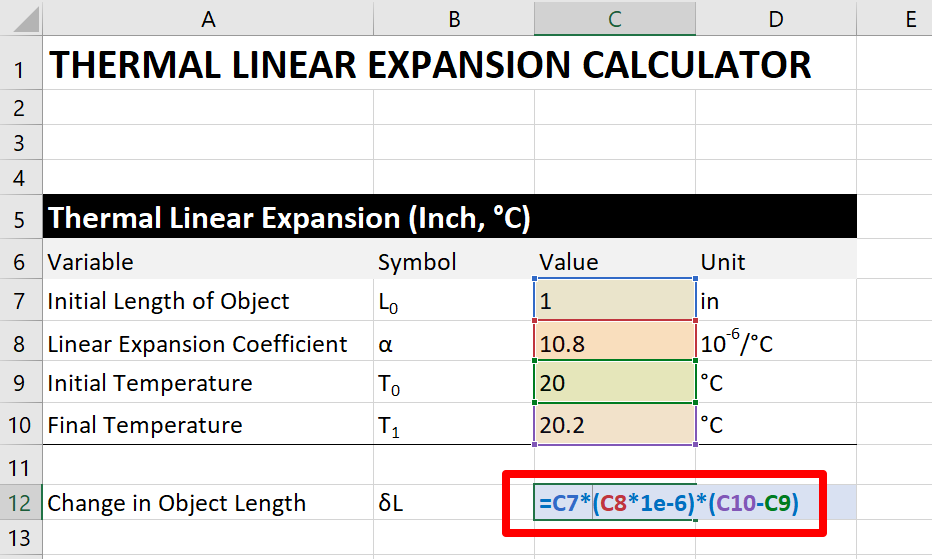

5c. Multiply by the original length

Now, multiply the result in step 5b by the original length. The result should be the change in the object’s length due to changes in temperature.

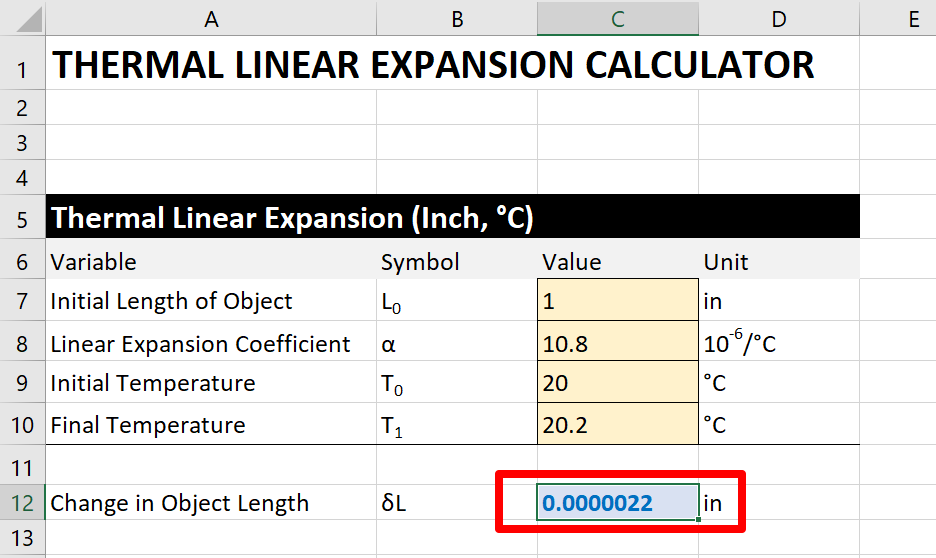

Step 6. Verify The Result

Finally, double check you work and verify the result is correct.

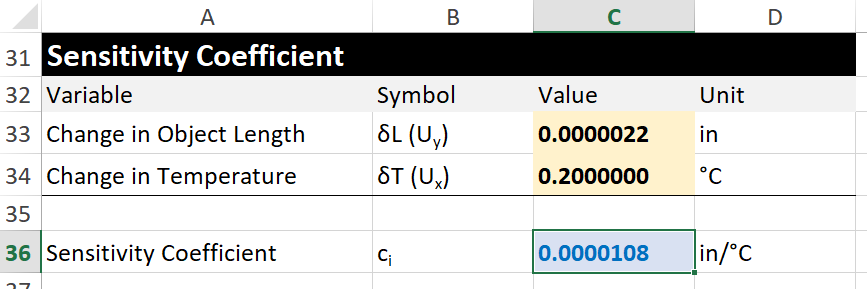

Step 7. Calculate the Sensitivity Coefficient (Optional)

If you prefer to use sensitivity coefficients in your uncertainty budgets, divide the change in object length (Uy) by the change in temperature (Ux). This will give you the sensitivity coefficient.

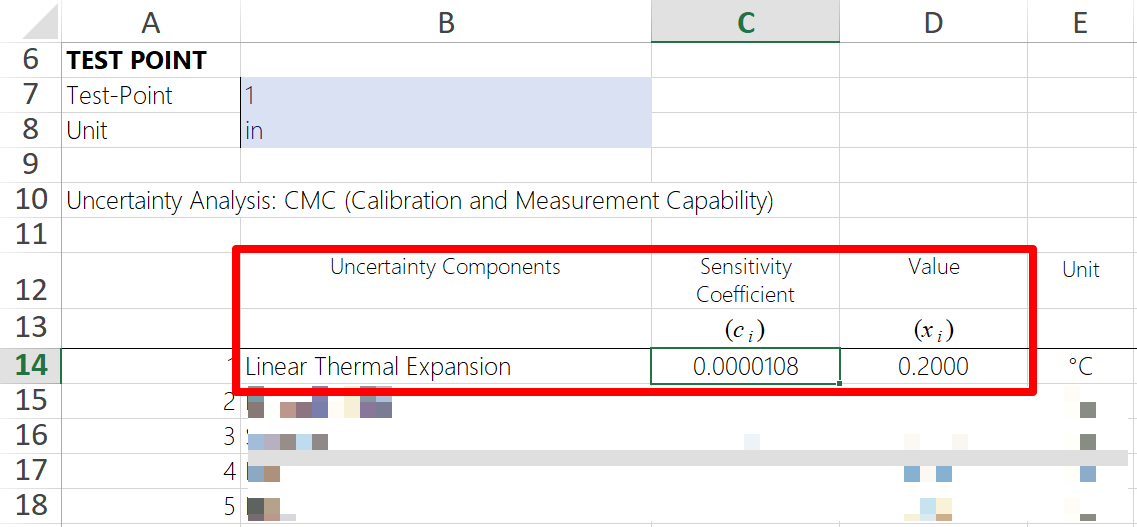

Now you can add the sensitivity coefficient and the change in temperature to your uncertainty budget.

Using sensitivity coefficients can come in handy if you need to update your uncertainty budget. You can simply update the change in temperature (Ux).

Common Examples of Thermal Linear Expansion

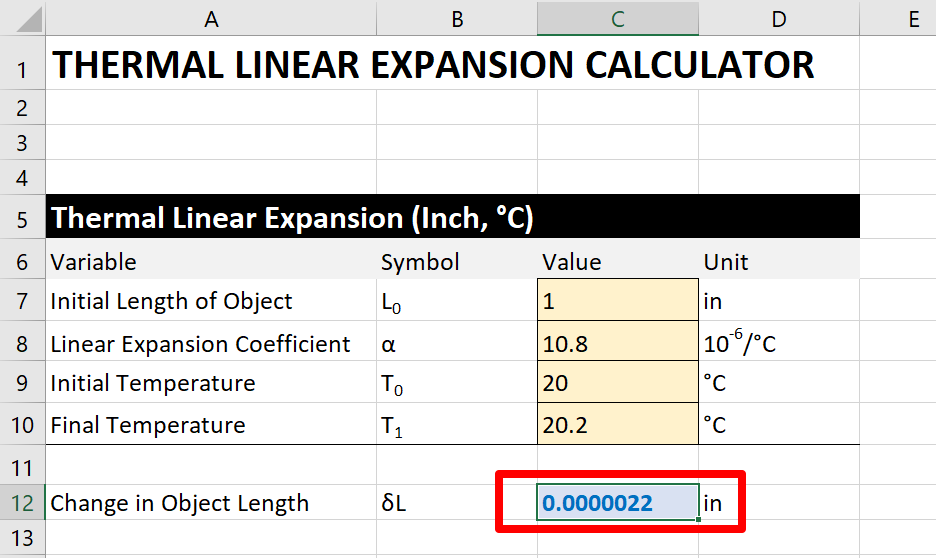

Example 1. Temperature change during test/calibration

One of the most common sources of uncertainty for thermal linear expansion is the change in temperature during testing or calibration.

Imagine that you are calibrating a caliper with a 1-inch stainless steel gauge block. When you begin the calibration, the temperature is 20 °C. When you finish the calibration, the temperature changed to 20.2 °C.

Using the thermal linear expansion equation, you find that the actual length of your gauge block changed 2.2 micro-inches.

If you do not correct for this at the time of test or calibration, then you should consider adding this source of uncertainty in your uncertainty budget.

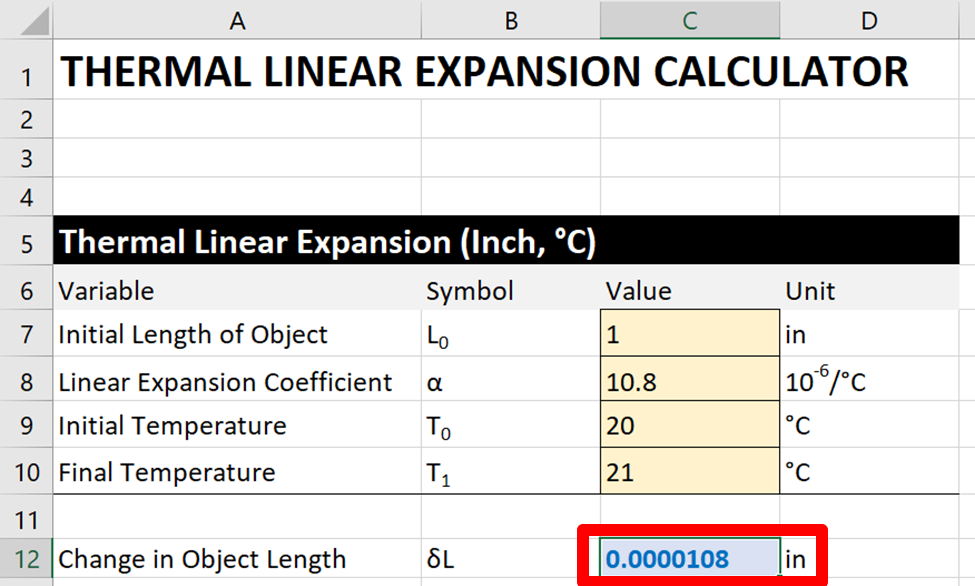

Example 2. Temperature difference between use and last calibration

Another common source of uncertainty for thermal linear expansion is the difference in temperature between the environment that an item is calibrated in versus the environment where it is used.

Imagine that you are calibrating a caliper with a 1-inch stainless steel gauge block. When you perform the calibration, the temperature is 21 °C. However, the gauge block was calibrated at 20 °C.

Using the thermal linear expansion equation, you find that the actual length of your gauge block changed 10.8 micro-inches.

If you do not correct for this at the time of test or calibration, then you should consider adding this source of uncertainty in your uncertainty budget.

Conclusion

Thermal expansion can affect your measurement results. It is a source of uncertainty that you should include in your uncertainty budgets if:

- You perform dimensional or mechanical tests or calibration,

- It’s effect is significant, and/or

- It’s effect is not corrected for.

When tighter tolerances are required, better quality measurements are important. Therefore, sources of measurement uncertainty, such as thermal expansion, need to be considered in your measurement results and minimized where practical.

In this guide, you should have learned the thermal linear expansion formula, how to calculate linear expansion, and how to include it in your uncertainty budgets.

Try adding it to your uncertainty budgets next time and let me know how it affected your measurement results.

Click here to download the thermal expansion calculator for free!

One Comment