Assessing Conformance to Specifications

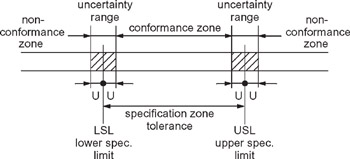

When a client requires a statement of conformance to predetermined specifications, there are several cases where the uncertainty in measurement has an influence on the statement of conformance. To properly assess conformance, add(subtract) the estimated expanded uncertainty to(from) the measurement result and determine which of the four following scenarios apply. Afterward, we can properly determine conformance, non-conformance, or neither. For laboratories that provide statements of conformance in their testing(calibration) reports, this is an important assessment that must be made prior to reporting the results.

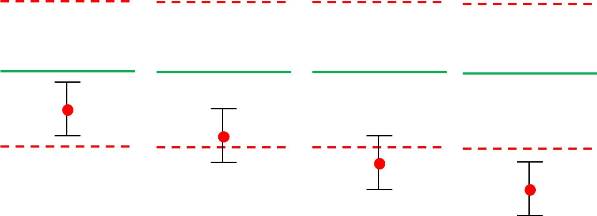

1 | Compliance (In Tolerance)

The measurement result is within limits, even when the uncertainty in measurement is taken into consideration. The result complies with specification.

2 | Compliance Undetermined

The measurement result is within limits by a margin less than required to state compliance by a 95% level of confidence. However the result indicates that compliance is more probable than non-compliance.

3 | Non-Compliance Undetermined

The measurement result is not within limits by a margin less than required to state non-compliance by a 95% level of confidence. However the result indicates that non-compliance is more probable than compliance.

4 | Non-Compliance (Out-of-Tolerance)

The measurement result is not within limits, even when the uncertainty in measurement is taken into consideration. The result does not comply with the specification.

Assessing compliance when the result is close to the Lower Limit