If you are an ISO/IEC 17025 accredited laboratory, you have probably heard the acronym CMC before. It is commonly used on a calibration laboratory’s scope of accreditation to express the laboratory’s measurement capability. If you are a testing laboratory, you are probably less familiar with this acronym; but, you shouldn’t be. Many testing laboratories are required to calculate the uncertainty in measurement results similar to calibration laboratories although your CMCs are not published in your scope of accreditation. Therefore, let’s discuss what a CMC is, how to estimate it’s value, and how to use it.

What is a CMC?

CMC is the abbreviation for ‘Calibration and Measurement Capability.’ It is defined by BIPM and ILAC as the calibration and measurement capability available to customers under normal conditions. When claiming a CMC, the measurement or calibration should be performed in accordance with a documented method or procedure and have an uncertainty budget associated with the process. Additionally, the process should be performed on a regular basis, whether scheduled or on demand, and the CMC should be made available to all clients.

To keep it simple, your CMC should publically express your calibration and measurement capability via a statement of uncertainty that follows a documented process and has an associated uncertainty budget.

Estimating a CMC

Your CMCs should be estimated using methods that comply with the Guide to the Expression of Uncertainty in Measurement (GUM). The estimation should be evidenced with an uncertainty budget which takes into account factors that significantly influence the measurement result. However, contributions caused by the unit under test (UUT) should normally be excluded from the CMC statement. These factors should be included in the estimation of the calibration or measurement uncertainty.

Some CMC Contributors;

- Repeatability

- Reproducibility

- Resolution

- Bias

- Drift

- Reference Standard Uncertainty

- Reference Standard Stability

- Environmental Factors

- Significant factors that influence the measurement result

Expressing a CMC

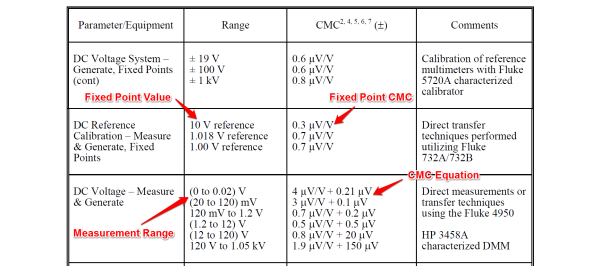

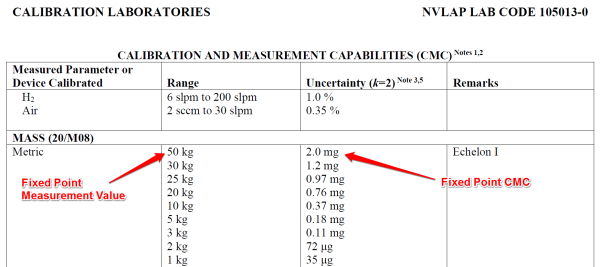

Once you have estimated your CMCs, there are typically four acceptable ways to express your CMCs; using a range, an equation, a fixed value, or a matrix. If you were to observe several scopes of accreditation, you will find the use of an equation or a fixed value to be the most common way to express a CMC uncertainty statement.

If you are expressing a CMC across the range of a function (i.e. DC Voltage Measure), I would recommend using an equation. Using an equation (typically) allows you to more adequately express that the uncertainty is directly proportional with range; uncertainty increases and the measured value increases or vice-versa. If you are expressing a CMC for a fixed value of a measurement function (i.e. Mass Measure), then it is typically best to use a fixed value for your CMC. However, sometimes it is acceptable to use a fixed value to express CMC uncertainty where the range of the measurement function is narrow and variance in the estimated uncertainty is low.

1 | Range

2 | Equation

3 | Fixed Value

4 | Matrix

Some Examples

Fluke – Everett Service Center

Henry Troemner LLC

Conclusion

CMCs should not be confused with the measurement uncertainty published in your calibration and test reports. The values expressed in your reports require some additional evaluation to include the influences introduced the unit under test. Your CMCs should only quantitatively express the measurement capability of your process minus the UUT.

13 Comments