Exemptions and uncertainty to two terms that are not commonly phrased together in metrology. However, ILAC has made provisions for exemptions to reporting uncertainty in measurement while maintaining requirements for accredited calibrations. This article will explore the three exemptions to reporting uncertainty in calibration reports as per the ILAC P14:01/2013.

If you are still reporting uncertainty in measurement, keep reading because you may stop reporting it today. ILAC has updated their P14 policy to accommodate the requirements of accreditation bodies, accredited laboratories, and their customers. In an effort to satisfy all parties, ILAC has published three exemptions to reporting uncertainty in calibration reports. As long as the criteria of the exemptions and the requirements of ISO/IEC 17025:2005 are maintained, accredited laboratories will be authorized to issue calibration reports without reporting statements of uncertainty.

“Make sure that you have covered this during contract review or you may end up having a nonconformance.”

I am sure that you have customers who could care less about measurement uncertainty, but want an accredited calibration. I know that I do. Well, you may be able to accommodate them if they do not intend to use calibration results to provide additional calibrations. All you need to do is get them to agree to it (in writing) during the contract review process.

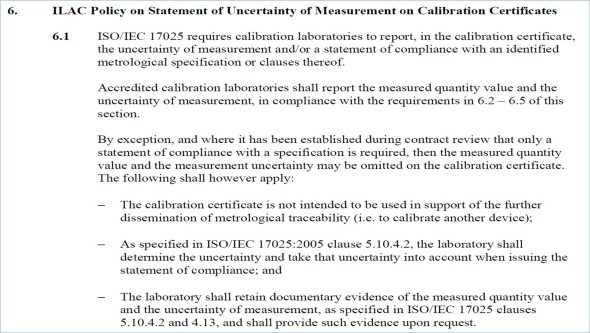

That’s right! If a customer agrees during contract review to omit the reporting of uncertainty in calibration reports, you don’t have to report it. If you are wondering how, refer to section 6.1 of the ILAC P14/01:2013 policy. It will explain everything.

Don’t want to look up it? No worries. I posted it here for you.

No More Calibrations

1. The calibration certificate is not intended to be used to support of the further dissemination of metrological traceability (i.e. to calibrate another device);

If the equipment that you are calibrating will not be used, by you or your customers, to calibrate other items, then you do not need to report measurement uncertainty in the calibration certificate. Utilizing this exemption allows you to omit it from the report completely. The only catch is you must meet the other two requirements for this exemption to be allowed.

Some of your clients may care about the uncertainty, but others will not. If your customers are not performing calibrations with their equipment, then they do not need measurement uncertainty statements in their reports. For these customers, get them to agree (in writing) to the exemption and omit reporting statements of uncertainty.

“Uncertainty in measurement is proportional to the length of the traceability chain. The longer the chain of traceability, the larger the uncertainty in measurement.”

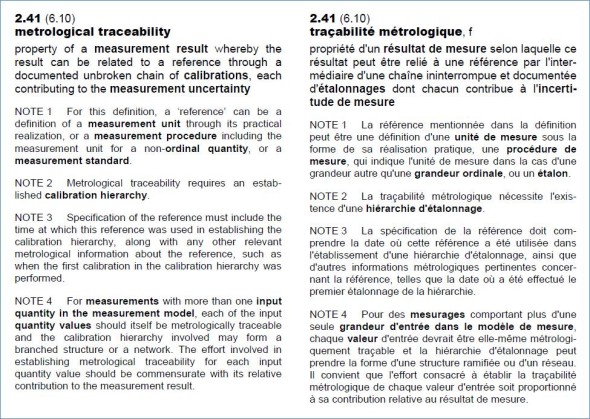

According the International Vocabulary of Metrology (VIM), Traceability is a property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of chain of calibrations, each contributing to the measurement uncertainty. See the excerpt below from the 2012 edition of the Vocabulary in International Metrology to read the full definition.

As you can see, you need the uncertainty in measurement to have traceability. As measurement systems are calibrated and move down the chain of traceability, the uncertainty in measurement should increase at each stage. This infers that uncertainty in measurement is proportional to the length of the traceability chain. The longer the chain of traceability, the larger the uncertainty in measurement. However, when the chain ends, the uncertainty will have reached its maximum value.

Each calibration depends on the measurement value and associated uncertainty of one or more reference standards. If the chain of traceability stops with you, then estimates of uncertainty are not needed for the next stage; hence, the rationale for the omission of uncertainty statements.

Statements of Conformance

2. As specified in ISO/IEC 17025:2005 clause 5.10.4.2, the laboratory shall determine the uncertainty and take that uncertainty into account when issuing the statement of compliance;

Does your laboratory provide statements of conformance (e.g. Pass, Fail, etc.) in your calibration certificates? If not, you have nothing to worry about. However, if you do, you will need to make sure that you take the uncertainty into account before claiming ‘Pass’ or ‘Fail.’

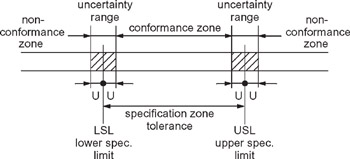

When a measurement result lands within the specifications or limits, it does not mean that the result is ‘in tolerance.’ Additionally, when a measurement result falls outside of the limits, it does not infer that the result is ‘out of tolerance.’ When measurement results are near the metrological specifications (i.e. limits), they are typically indeterminate. If you take the measurement uncertainty into account, you may not be able to confidently determine whether the measurement result is in or out of tolerance.

Look at the image below. The uncertainty range around the limits exhibits the indeterminate zone. If your measurement results fall within the conformance zone, it is safe to claim ‘Pass’ or ‘In Tolerance.’ If your measurement results fall in the nonconformance zone, it is okay to state ‘Fail’ or “Out of Tolerance.’ When results land in the indeterminate zone, it is impossible to confidently determine conformance or nonconformance.

So if you plan to omit reporting uncertainty, make sure that you take the uncertainty into account before providing statements of conformance. If you are like me, then do not give statements of conformance and bypass this requirement altogether.

Maintain Good Records

3. The laboratory shall retain documentary evidence of the measured quantity value and the uncertainty of the measurement, as specified in ISO/IEC 17025 clauses 5.10.4.2 and 4.13, and shall provide such evidence upon request.

Just because you have now decided to stop reporting uncertainty, you must still estimate the uncertainty in measurement and keep a record of it. That’s right! You need to have a record of the calculation available upon request should your assessor ask for it. Better yet, make sure you maintain records in case your customer changes their mind and wishes to have the uncertainty in measurement reported in the calibration certificate.

You did not think it was going to that easy did you. How else would you take uncertainty into account if making statements of conformance? So, you may asking yourself, “What is the benefit to not reporting uncertainty?”

Benefits: What’s In It For Me?

From my experience, there are a few benefits for the laboratory. First, data entry time is cut in half. You have to calculate uncertainty, which can be automated, but you do not need to enter the data into the calibration report saving you data entry time and doubling your productivity. Second, you will have less mistakes and fewer non-conformances. The more manual data that you enter, the more likely you are subjected to human error. More errors equal more non-conformities, more paperwork, more time, and less production.

Finally, you will reduce lost production due to customer inquiries. I am sure you have customers who call wanting explanations about measurement uncertainty; “What is it?,” “Why is it in the report?,” and(or) “Why does it matter?” Time spent on the phone giving education and explanation is good customer service but a huge time waster. This lost time causes lost productivity and smaller profits. If you are a small business where time matters, this is critical!

So, you may not get out of doing the work of estimating uncertainty, but you will be able to save time (which equates to dollars) on data entry by not having to report uncertainty in your calibration reports. However, I cannot emphasize enough to make sure that you have covered this during contract review or you may end up having a nonconformance.

One Comment