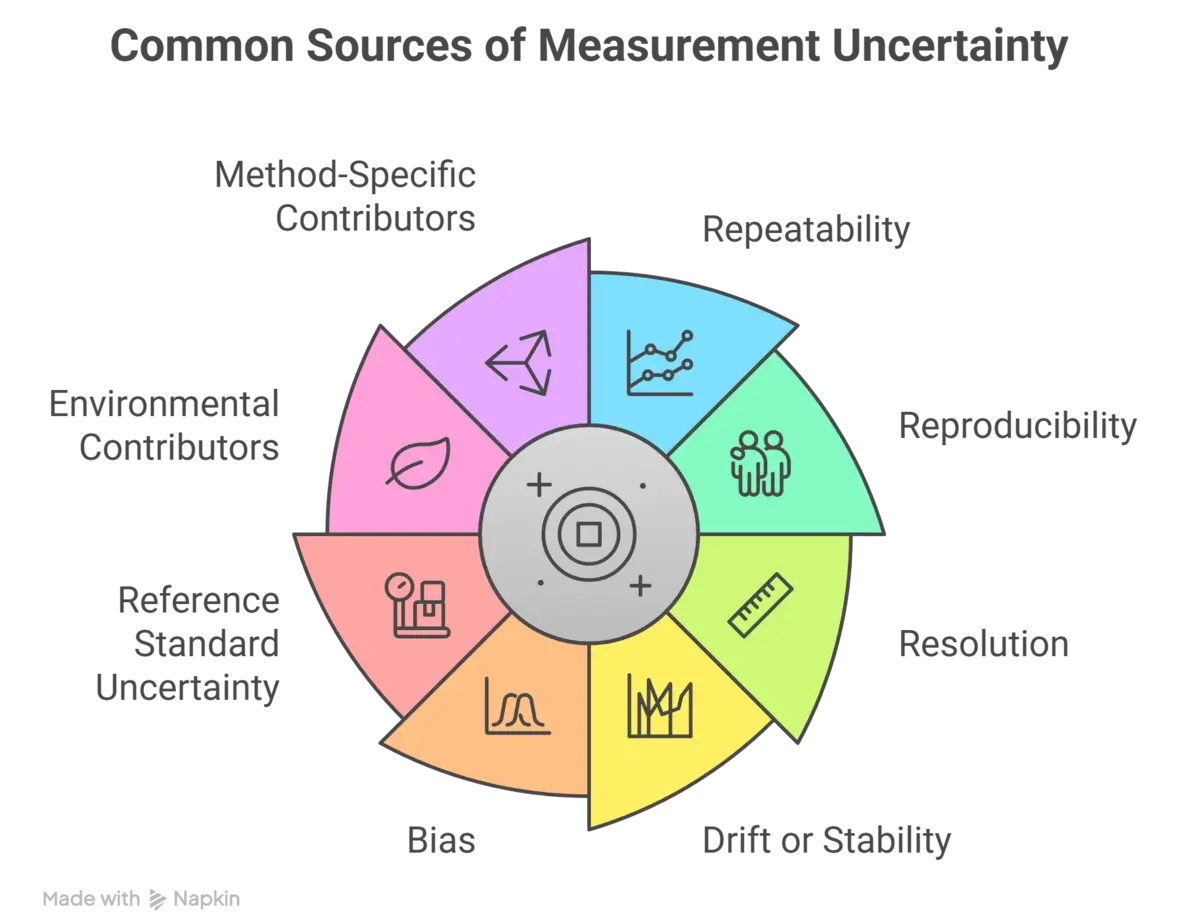

Short answer: The most significant sources of uncertainty vary with each type of test, measurement, and measurement system. However, some of the most common sources of uncertainty that significantly affect measurement results include:

- Repeatability,

- Reproducibility,

- Resolution,

- Drift or Stability,

- Bias,

- Reference Standard Uncertainty,

- Environmental Contributors, and

- Method-specific Contributors.

Every test and measurement is different. Likewise, the most significant contributors will not be the same.

Some tests and measurements will be heavily influenced by repeatability and reproducibility. Some will be significantly affected by drift or bias while others are significantly impacted by instrument resolution or environmental factors.

The only way to know which sources are the most significant is to evaluate measurement uncertainty and calculate the percentage of the total variance (i.e. Factor Analysis) each source of uncertainty has on the combined standard measurement uncertainty.

Examples

Example 1: Drift, Bias, and Reference Standard Uncertainty

Stable, repeatable, and reproducible measurements are likely influenced by drift, bias, calibration uncertainties.

For example, some precision multimeters have high resolution and the capability to repeat measurement results with low variability. In this scenario, factors like drift, bias, or reference standard uncertainty will be the most significant source of uncertainty.

Example 2: Repeatability and Reproducibility

Unstable, less repeatable measurements are likely influenced by Type A uncertainties, such as repeatability and reproducibility.

For example, pipetting is a skill. Typically, there is a degree of variability in reproducible results between different operators. Therefore, repeatability and reproducibility are usually significant sources of uncertainty.

Another example is calibrating a torque wrench. Obtaining repeatable measurements is a skill, and the variability in reproducible results between operators is likely. Therefore, repeatability and reproducibility are usually significant sources of uncertainty.

Example 3: Environmental Contributors

Measurements that are sensitive to environmental conditions will likely have environmental factors such as temperature, pressure, etc as the most significant sources of uncertainty. For example, a CMM is capable of producing accurate and repeatable results. However, environmental factors such as temperature can affect its performance making it a significant source of uncertainty.

Another example is volumetric flow. No matter how accurate or repeatable the device is, results can be significantly impacted by environmental factors such as temperature and pressure. In my experience, the reference temperature has been the biggest factor when evaluating interlaboratory comparison results. When the reference temperature is unknown or different and the results are not standardized to normal temperature and pressure (NTP), the effects on measurement uncertainty are very significant.

Example 4: Resolution

Equipment that lacks enough resolution to see variability in results will result in resolution being the largest contributor to uncertainty.

For example, the measurement uncertainty of a low resolution, dial caliper measuring a gauge block will have its resolution as the most significant contributor. Typically, the uncertainties related to the gauge block, the measurement process, and environmental conditions will be significantly less than the resolution of the caliper. Therefore, the uncertainty will be dominated by the resolution. Even the estimate of measurement repeatability will be limited by the resolution if all the repeated results are the same (i.e. no variation). See JCGM 100:2008, section F.2.1.1 for guidance to estimate repeatability in this scenario.

FAQ

What are the main sources of uncertainty?

The main sources of uncertainty in testing and calibration activities are given in the list below. Each of these represent a main category which all other sources of uncertainty can be grouped under.

- Method

- Equipment

- Personnel

- Environment

- Item or Unit Under Test

- Reference Standard

How to calculate the most significant sources of uncertainty?

To determine the most significant sources of uncertainty, conduct a Factor Analysis to calculate the proportion or percentage of the total variance. The sources of uncertainty with higher percentages will be the most significant.

Follow the instructions below to calculate the percentage of total variance:

- Calculate the variance – square each standard measurement uncertainty.

- Calculate total variance – square the combined standard measurement uncertainty.

- Divide each variance by the total variance.

- Multiply the result by 100 to convert it to a percentage.

- Find the uncertainties with the higher percentages.

How do you determine which sources of uncertainty to include in an uncertainty budget?

Conduct research to find all potential sources of uncertainty associated with the test or measurement, including the method, personnel, equipment, reference standards, environment, and unit/item under test.

Common resources used to find sources of uncertainty include:

- Measurement/Test methods,

- Manufacturer manuals and specifications,

- Reference standard calibration reports,

- Reference materials certificates of analysis,

- Measurement-specific guidance documents,

- Scientific journals,

- Conference papers,

- Uncertainty budgets from other labs,

- Proficiency testing and interlaboratory comparison results,

- Experimental results,

- and more

How do random and systematic errors contribute to overall measurement uncertainty?

They both contribute to the total combined measurement uncertainty. Each error source is converted to a standard deviation equivalent (i.e. standard uncertainty) and combined in quadrature using the square root of the sum of squares (RSS) method to calculate the combined standard uncertainty. Then, the uncertainty can be expanded to a desired confidence interval by multiplying the combined uncertainty by a coverage factor.

According to the GUM (JCGM 100:2008), Recommendation INC-1 (1980) replaced the terms random and systematic uncertainties with Type A and Type B uncertainty.

Random uncertainties would be best associated with Type A uncertainty, where the magnitude of uncertainty is evaluated by statistical methods (typically ANOVA).

Systematic Uncertainty would be best associated with Type B Uncertainty, where the magnitude of uncertainty is evaluated by techniques other than statistical means (but not always). Systematic is defined as “of a system.” Therefore, you would want to evaluate sources of uncertainties that are “of the system” and not associated with random uncertainties.

Glossary

- Significant Contributor (to Uncertainty)

- an uncertainty contributor whose contribution increases the CMC uncertainty by five percent (5%) or greater. (Source: A2LA R205, 6.0)

- Combined Standard Measurement Uncertainty

- standard measurement uncertainty that is obtained using the individual standard measurement uncertainties associated with the input quantities in a measurement model. (Source: JCGM 200:2012, 2.31)

- Measurement Repeatability

- measurement precision under a set of repeatability conditions of measurement (Source: JCGM 200:2012, 2.21)

- Repeatability Condition of Measurement

- condition of measurement, out of a set of conditions that includes the same measurement procedure, same operators, same measuring system, same operating conditions and same location, and replicate measurements on the same or similar objects over a short period of time (Source: JCGM 200:2012, 2.20)

- Measurement Reproducibility

- measurement precision under reproducibility conditions of measurement (Source: JCGM 200:2012, 2.25)

- Reproducibility Condition of Measurement

- condition of measurement, out of a set of conditions that includes different locations, operators, measuring systems, and replicate measurements on the same or similar objects (Source: JCGM 200:2012, 2.24)

- Instrumental Drift

- continuous or incremental change over time in indication, due to changes in metrological properties of a measuring instrument (JCGM 200:2012, 4.21)

- Instrumental Bias

- average of replicate indications minus a reference quantity value (JCGM 200:2012, 4.20)

- Measurement Bias

- estimate of a systematic measurement error (JCGM 200:2012, 2.18)

- Resolution

- smallest change in a quantity being measured that causes a perceptible change in the corresponding indication (JCGM 200:2012, 4.14)

- Reference Measurement Standard

- measurement standard designated for the calibration of other measurement standards for quantities of a given kind in a given organization or at a given location (JCGM 200:2012, 5.6)

- Type A Evaluation of Measurement Uncertainty

- evaluation of a component of measurement uncertainty by a statistical analysis of measured quantity values obtained under defined measurement conditions (JCGM 200:2012, 2.28)

- Type B Evaluation of Measurement Uncertainty

- evaluation of a component of measurement uncertainty determined by means other than a Type A evaluation of measurement uncertainty (JCGM 200:2012, 2.29)