Introduction

Measurement traceability is an important factor for your laboratory to meet the requirements of ISO/IEC 17025 accreditation. In fact, measurement traceability is one of the top 10 cited deficiencies of all ISO/IEC 17025 audits.

If you are not currently meeting this requirement, I encourage you to read this article to learn how to get your measurement results traceable to the SI.

Background

If you are not familiar with my business, I provide consulting services for laboratories seeking ISO/IEC 17025 accreditation. Most of the time, companies hire me to calculate uncertainty for their scope of accreditation.

So, I calculate uncertainty a lot!

One of the data sources that I use to create uncertainty budgets is calibration reports. Many times, customers send me calibration reports issued from the manufacture or a non-accredited calibration laboratory. Typically, the calibration is not accredited nor do their reports include estimates of measurement uncertainty.

When this happens, I am unable to adequately estimate uncertainty for the customer’s scope of accreditation.

Additionally, the customer is at risk of not meeting the traceability requirements of the ISO/IEC 17025 standard.

So, I decided to write a guide that clearly explains measurement traceability to teach you how to obtain traceability for your measurement results. At the end of this guide, I am going to layout a four-step process you can implement to help you obtain measurement traceability.

Below is a list of topics that I will cover in this guide.

1. What is Measurement Traceability

2. Why is Measurement Traceability Important

3. How Does Traceability Affect Measurement Uncertainty

4. Measurement Traceability Requirements of ISO/IEC 17025

5 Measurement Traceability Using External Services

6 Common Problems With Measurement Traceability

7. International Agreements on Measurement Traceability

8. Measurement Traceability Policies and Guides

9. How to Obtain Measurement Traceability

10. Traceability Statements in Testing and Calibration Reports

11. NIST Traceable Numbers

What is Measurement Traceability?

According to International Vocabulary of Metrology (VIM), Metrological Traceability or Measurement Traceability is a “property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty.”

In addition to the definition, the VIM provides some supplementary notes that should be taken into consideration;

“NOTE 1 For this definition, a ‘reference’ can be a definition of a measurement unit through its practical realization, or a measurement procedure including the measurement unit for a non-ordinal quantity, or a measurement standard.

NOTE 2 Metrological traceability requires an established calibration hierarchy.

NOTE 3 Specification of the reference must include the time at which this reference was used in establishing the calibration hierarchy, along with any other relevant metrological information about the reference, such as when the first calibration in the calibration hierarchy was performed.

NOTE 4 For measurements with more than one input quantity in the measurement model, each of the input quantity values should itself be metrologically traceable and the calibration hierarchy involved may form a branched structure or a network. The effort involved in establishing metrological traceability for each input quantity value should be commensurate with its relative contribution to the measurement result.”

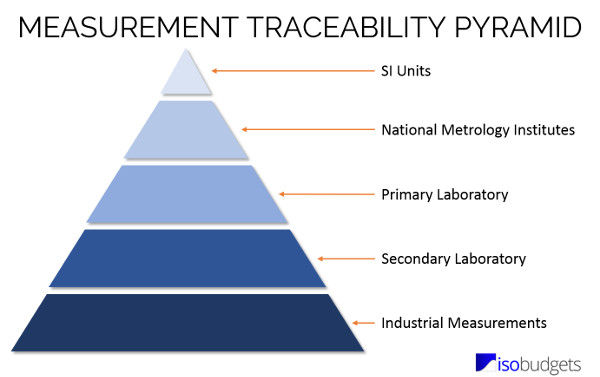

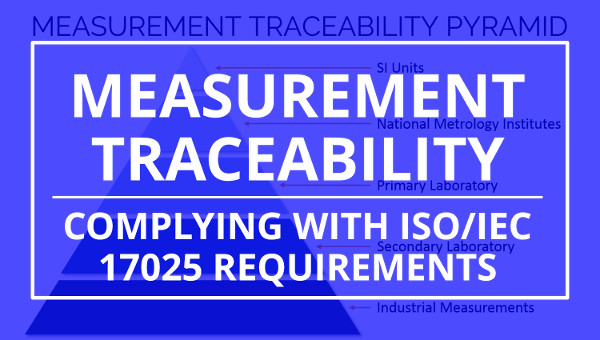

Below is an image of the measurement traceability pyramid. It is the most commonly used graphical representation to demonstrate measurement traceability and the calibration hierarchy from the realization of the SI Unit down to the measurements performed in the industrial environment.

Why is Measurement Traceability Important?

Measurement traceability is important because it gives you confidence and assurance that your measurement results agree with national or international standards within the statement of uncertainty in measurement.

Without traceability, a laboratory can claim anything they want in a test or calibration report. With traceability and the independent verification of an accreditation or inspection body, you can minimize the risk of falling victim to fraudulent information and activities.

The important thing to remember is the results you report to your customers may be used to provide calibrations, perform tests, manufacture products, or make decisions which could affect health, safety, and even court proceedings. It is a big deal!

Think about it for a minute…

If you provide results to a manufacture that makes or services aircraft, you could be putting other people’s lives at risk. Would you put your family on that plane?

Another customer of yours could be using equipment to make medical decisions that affect someone’s health. What is the patient was your spouse or child?

Maybe your results will be used in court as evidence which can affect the outcome of a case. Would you be confident if you were on trial for murder?

While some of these examples are extreme, they are real world scenarios that happen everyday. The work that you perform in the laboratory can significantly impact society. This is why measurement traceability is important.

How Does Traceability Affect Measurement Uncertainty

Measurement traceability can have a direct impact on the uncertainty of your measurement results.

Have you ever considered how your measurement uncertainty is affected by where you send your equipment for calibration?

Well, the estimates of measurement uncertainty that you publish in your scope of accreditation and in your test and calibration reports are directly affected by metrological traceability.

When you send your equipment out for calibration, you normally receive a calibration report when the instruments are returned to you. In these reports are estimates of measurement uncertainty that are associated with the reported measurement results.

The uncertainty estimates in these reports are your traceable uncertainty, and are commonly referred to as calibration uncertainty or reference standard uncertainty.

This uncertainty will be used in your uncertainty budgets to estimate your Calibration and Measurement Capability (CMC) uncertainty published in your scope of accreditation.

Typically, the shorter the chain between your laboratory and a national metrology institute, the smaller the uncertainty in measurement you can expect to see.

For example, if you send your PRT Thermometer to NIST for calibration, you should expect to see less uncertainty in measurement than if you sent it to an accredited calibration laboratory.

So, if your goal is to perform measurements with less uncertainty, be sure to review your calibration laboratory’s scope of accreditation before sending in your equipment for calibration.

Traceability Requirements of ISO/IEC 17025

If your laboratory is seeking ISO/IEC 17025 accreditation, you will need to ensure that your quality system meets the requirements of the international standard.

In this section, I will cover the requirements of the ISO/IEC 17025 standard and the ILAC P10 policy on traceability. If you are unfamiliar with either one of these documents, I recommend that you read them both.

General Traceability Requirements

In section 5.6 of the ISO/IEC 17025, the standard states the following:

“5.6.1 General

All equipment used for tests and/or calibrations, including equipment for subsidiary measurements (e.g. for environmental conditions) having a significant effect on the accuracy or validity of the result of the test, calibration or sampling shall be calibrated before being put into service. The laboratory shall have an established programme and procedure for the calibration of its equipment.

NOTE Such a programme should include a system for selecting, using, calibrating, checking, controlling and maintaining measurement standards, reference materials used as measurement standards, and measuring and test equipment used to perform tests and calibrations.”

In summary;

• If the equipment you use has a significant effect on your measurement results, it should be calibrated.

• You need a program and a procedure for calibrating your equipment.

Traceability Requirements for Calibration Laboratories

If you are a calibration laboratory, the ISO/IEC 17025 standard states:

“5.6.2.1.1 For calibration laboratories, the programme for calibration of equipment shall be designed and operated so as to ensure that calibrations and measurements made by the laboratory are traceable to the International System of Units (SI) (Système international d’unités).

A calibration laboratory establishes traceability of its own measurement standards and measuring instruments to the SI by means of an unbroken chain of calibrations or comparisons linking them to relevant primary standards of the SI units of measurement. The link to SI units may be achieved by reference to national measurement standards. National measurement standards may be primary standards, which are primary realizations of the SI units or agreed representations of SI units based on fundamental physical constants, or they may be secondary standards which are standards calibrated by another national metrology institute.

When using external calibration services, traceability of measurement shall be assured by the use of calibration services from laboratories that can demonstrate competence, measurement capability and traceability. The calibration certificates issued by these laboratories shall contain the measurement results, including the measurement uncertainty and/or a statement of compliance with an identified metrological specification (see also 5.10.4.2).”

Furthermore, the standard has requirements for your reference standards:

“5.6.3.1 The laboratory shall have a programme and procedure for the calibration of its reference standards. Reference standards shall be calibrated by a body that can provide traceability as described in 5.6.2.1. Such reference standards of measurement held by the laboratory shall be used for calibration only and for no other purpose, unless it can be shown that their performance as reference standards would not be invalidated. Reference standards shall be calibrated before and after any adjustment.”

In summary;

• You need to establish traceability via an unbroken chain of calibrations linking your measurement standards to primary standards of the SI units of measure.

• You need to use calibration services that are competent, capable, and traceable.

Traceability for Testing Laboratories

If you are a testing laboratory, the ISO/IEC 17025 standard states:

“5.6.2.2.1 For testing laboratories, the requirements given in 5.6.2.1 apply for measuring and test equipment with measuring functions used, unless it has been established that the associated contribution from the calibration contributes little to the total uncertainty of the test result. When this situation arises, the laboratory shall ensure that the equipment used can provide the uncertainty of measurement needed.

NOTE The extent to which the requirements in 5.6.2.1 should be followed depends on the relative contribution of the calibration uncertainty to the total uncertainty. If calibration is the dominant factor, the requirements should be strictly followed.”

In addition to the ISO/IEC 17025 standard, the ILAC P10 policy states:

“5) If the calibration of instruments used in testing contributes significantly to the overall uncertainty, the same policy for traceability applies (as detailed under 1) to 4) above).

6) If a calibration is not a dominant factor in the testing result, the laboratory shall have quantitative evidence to demonstrate that the associated contribution of a calibration contributes little (insignificantly) to the measurement result and the measurement uncertainty of the test and therefore traceability does not need to be demonstrated.”

In summary;

• If your lab equipment affects the uncertainty of your test result, it should be calibrated.

• If your lab equipment does not affect the uncertainty of the test result and you believe that you do not need measurement traceability, you better have objective evidence to support your decision.

Measurement Traceability Using External Services

When it comes to obtaining metrological traceability by using external services, you typically have three options:

• Traceability via a National Metrology Institute

• Traceability via an accredited calibration laboratory

• Traceability via certified reference materials

Traceability via a National Metrology Institute

If you plan to use a National Metrology Institute to obtain metrological traceability, you need to ensure that their services are covered by the CIPM MRA.

To verify the NMI’s services are covered, you will need to make sure that their services are listed in Appendix C of the BIPM Key Comparison Database (KCDB). Verify that the service listing includes the measurement range and uncertainty.

The ILAC P10 policy on traceability states:

“1) An NMI whose service is suitable for the intended need and is covered by the CIPM MRA. Services covered by the CIPM MRA can be viewed in Appendix C of the BIPM KCDB which includes the range and uncertainty for each listed service.

3a) An NMI whose service is suitable for the intended need but not covered by the CIPM MRA. In this case the accreditation body shall establish a policy to ensure that those services meet the relevant criteria for metrological traceability in ISO/IEC 17025:2005.”

Traceability via an Accredited Calibration Laboratory

If you intended to obtain metrological traceability from an ISO/IEC 17025 accredited calibration laboratory, you will need to ensure that the services you need are listed in their scope of accreditation. Additionally, you will need to verify that their accreditation body is covered by the ILAC Mutual Recognition Arrangement.

To check that the accreditation body is a signatory, you can use ILAC’s MRA Signatory Search database.

If the accreditation body is listed, they are a signatory and acceptable for use.

The ILAC P10 policy on traceability states:

“2) An accredited calibration laboratory whose service is suitable for the intended need (i.e, the scope of accreditation specifically covers the appropriate calibration) and the Accreditation Body is covered by the ILAC Arrangement or by Regional Arrangements recognised by ILAC.

3b) A calibration laboratory whose service is suitable for the intended need but not covered by the ILAC Arrangement or by Regional Arrangements recognised by ILAC. In these cases the accreditation body shall establish a policy to ensure that those services meet the relevant criteria for metrological traceability in ISO/IEC 17025:2005.”

Traceability via a Certified Reference Materials

If you intended to obtain metrological traceability from reference materials, the ISO/IEC 17025 standard states:

“5.6.3.2 Reference materials

Reference materials shall, where possible, be traceable to SI units of measurement, or to certified reference materials.”

Currently, the ILAC MRA does not cover the accreditation of reference material producers. However, they have established policies to help you meet traceability requirements via reference materials.

The policies below are provided from section 4 of the ILAC P10 policy.

“7) The values assigned to CRMs produced by NMIs and included in the BIPM KCDB or produced by an accredited RMP under its accredited scope of accreditation to ISO Guide 34:2009 [5], are considered to have established valid traceability (see ILAC General Assembly resolution ILAC 8.12).

8) The values assigned to CRMs covered by entries in the JCTLM database are considered to have established valid traceability.

9) The majority of RMs and CRMs are produced by other RMPs. These can be considered as critical consumables and the laboratory shall demonstrate that each RM or CRM is suitable for its intended use as required by clause 4.6.2 in ISO/IEC 17025:2005 or ISO 15189:2007.”

In summary;

• Reference materials provided by National Metrology Institutes that are included in the BIPM Key Comparison Database are considered traceable.

• Reference materials provided by National Metrology Institutes that are included in the BIPM Joint Committee for Traceability in Laboratory Medicine Database are considered traceable.

• Reference materials provided by reference material producers who are accredited to ISO Guide 34 and covered under their scope of accreditation are considered traceable.

• Reference materials produced by non-accredited reference material producers must be demonstrated as suitable for intended use in accordance with ISO/IEC 17025, section 4.6.2.

Common Problems With Measurement Traceability

According to ILAC, there are two common problems associated with measurement traceability;

• Misconception of Measurement Traceability

• Harmonizing Measurement Traceability

In the section below, I will show you more about some of the common problems associated with traceability.

Misconception of Measurement Traceability

The ILAC P10 policy provides a great explanation of what measurement traceability is not:

“The persistent misconception that metrological traceability may be linked to a particular organization (e.g., “traceable to a specific National Metrology Institute”) fosters continued confusion with regard to its nature. Metrological traceability pertains to reference quantity values of measurement standards and results, not the organization providing the results.”

Think about that next time you read a traceability statement that declares “traceable to NIST.”

Harmonizing Measurement Traceability

Additionally, ILAC identifies several factors that prevent world-wide harmonization of a measurement traceability policy:

“Factors that influence the establishment of a harmonised ILAC policy on metrological traceability of measurement results include the following:

(a) The concept of metrological traceability of measurement results in fields such as the chemical, medical, and biological sciences is still under development;

(b) Not all economies have the complete range of national measurement standards or calibration and measurement capabilities needed to support the calibration and testing needs of all applicants for accreditation in their economy;

(c) The role of reliable and traceable certified reference materials in providing metrological traceability of measurement results has not yet been fully established internationally.”

International Agreements on Measurement Traceability

There are two major international recognition agreements on measurement traceability. They are the CIPM MRA and the ILAC MRA.

CIPM Mutual Recognition Agreement

The CIPM is an international committee of 18 members who promote world-wide uniformity in units of measurement. To accomplish international equivalence in measurements, they have created the CIPM MRA.

The CIPM Mutual Recognition Agreement (MRA) is an open and transparent system where National Metrology Institutes provide information on the comparability of their services and measurement standards. Participating institutes have their calibration and measurement capabilities (CMC) peer-reviewed and approved before they are published in the CIPM MRA database, also known as the BIPM Key Comparison Database (KCDB).

If you are obtaining metrological traceability via a National Metrology Institute, verify that they are a signatory to the CIPM MRA and that their measurement services are published in the BIPM Key Comparison Database (KCDB).

Click here for a full list of National Metrology Institutes that are signatories to the CIPM MRA.

ILAC Mutual Recognition Agreement

ILAC is an international organization for accreditation bodies operating in accordance with ISO/IEC 17011 that accredit laboratories seeking ISO/IEC 17025, ISO 15189, and ISO/IEC 17020 accreditation.

The goal of the ILAC Mutual Recognition Arrangement (MRA) is to develop an international network of accredited laboratories and promote the mutual acceptance of their test and calibration data for international trade and commerce.

To ensure that you are obtaining metrological traceability from a laboratory that is accredited via a signatory to the ILAC MRA, check out the ILAC MRA Signatory Search Database.

Measurement Traceability Policies and Guides

In this section is a list of popular measurement traceability policies. Most importantly, I have included the ILAC policy on traceability. Plus, you will find links to NIST’s policy on traceability. Furthermore, I have included the measurement traceability policies of each accreditation body in North America.

ILAC

ILAC P10:01/2013 ILAC Policy on Traceability of Measurement Results

NIST

NIST Policy on Metrological Traceability

NIST Policy on Traceability Supplemental Materials

A2LA

A2LA P102 – Policy on Metrological Traceability

NVLAP

NVLAP Resources for Traceability and Uncertainty

ANAB

ANAB GD 2002 – Guidance on Metrological Traceability

IAS

PJLA

PJLA PL-2 – Measurement Traceability Policy

How to Obtain Measurement Traceability

Ensuring that your measurement results are traceable is not difficult, but sometimes it helps to have a procedure. So, I am going to teach you step by step how to obtain measurement traceability.

Below, I have outlined a four step procedure that you can easily apply in your company or laboratory.

1. Determine What Measurement Functions Require Traceability.

First, you need to determine what measurement functions or capabilities require traceability.

For example, you own a set of gage blocks that need to be calibrated, and you want to make sure that your measurements are traceable. The measurement function for this example would be length.

2. Search for An ISO/IEC 17025 Accredited Laboratory

Now that you know what measurement function requires traceability, you need to find a laboratory that can provide ISO/IEC 17025 accredited calibration services.

The easiest way to ensure that your calibration results will meet traceability requirements is to send your equipment directly to a National Metrology Institute or to an ISO/IEC 17025 accredited calibration laboratory.

To find a National Metrology Institute, search the CIPM MRA signatory database. Then, make sure that the calibration service that you need is covered in the BIPM Key Comparison Database (KCDB).

To find an accredited laboratory, visit your preferred accreditation body’s website and search their accredited laboratory database. If you are unsure where to begin, I have provided some links for you below.

A2LA Directory of Accredited Organizations

ANAB Accredited Company Search

PJLA List of Accredited Laboratories

When you visit an accreditation body’s website, you will want to search their database of accredited laboratories. If you are unable to find their database, use the links that I have provided or give the accreditation body a call. I am sure that they will be glad to help you.

Once you access the accredited laboratory database, search for laboratory’s using the your measurement function as the keywords.

For our example, search the database using the keywords “length” or “gage blocks.”

The database search will return a list of laboratories that you can hire to calibrate your equipment.

However, before sending your equipment to any laboratory, I recommend that you review their scope of accreditation to verify that it lists the measurement function that you need for measurement traceability.

After you verify that a laboratory has the measurement function listed in their scope of accreditation, contact them to inquire about services, scheduling, and pricing. Be sure to request an ISO/IEC 17025 accredited calibration.

Depending on your goals and requirements, I recommend that you do not choose a laboratory based on price alone. Try looking at the measurement uncertainty listed in their scope of accreditation. Typically, the smaller the uncertainty, the better quality in measurement results.

So, buyer beware! Do your research and do not be afraid to ask questions. If the laboratory has competent personnel, they will not have a problem answering your questions.

3. Submit Your Equipment For Calibration

After selecting a laboratory, send your equipment in for calibration. When you receive it back, it should be returned with a calibration certificate.

You will want to review the calibration certificate to verify that all of the traceability requirements for ISO/IEC 17025 have been met.

4. Review Your Calibration Report

To ensure that you have measurement traceability, review the calibration report and make sure that it bears the accreditation body symbol of the laboratory, contains measurement results, provides an associated estimate of uncertainty in measurement, and has a description of the reference standard.

To Recap:

Follow the summarized steps below to make sure you are getting traceability for your measurement results.

1. Determine What Measurement Functions Require Traceability.

2. Search for An ISO/IEC 17025 Accredited Laboratory

a. Visit Preferred Accreditation Body Website

b. Search Accredited Laboratory Database

c. Search for Laboratory Capability

d. Verify Scope of Accreditation

e. Contact the Laboratory

3. Submit Your Equipment For Calibration

4. Review Your Calibration Report

a. Accreditation Body Symbol

b. Measurement Result

c. Measurement Uncertainty

d. Description of the Reference Standard

Traceability Statements in Testing and Calibration Reports

If your laboratory issues test and(or) calibration reports to your customers, it customary to include a statement of measurement traceability in your certificate. In fact, Section 5.10.2 of the ISO/IEC 17025:2005 standard requires that your reports include a traceability statement.

Now, I know that most of you are probably not word smiths or copywriters, so I have curated some examples of measurement traceability statements to help you write your own.

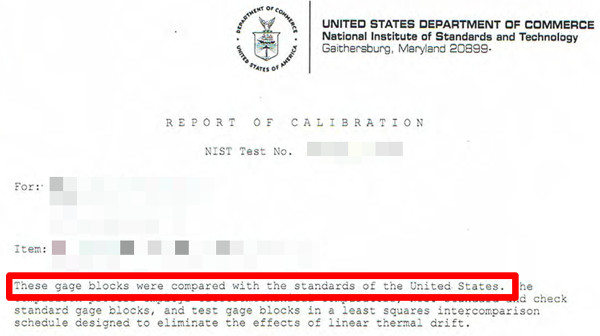

NIST – National Institute of Standards and Technology

“These gage blocks were compared with standards of the United States.”

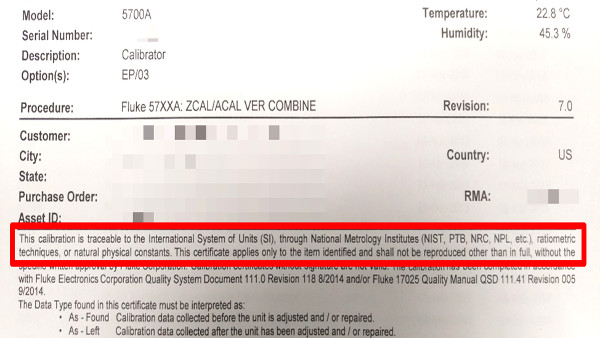

FLUKE Calibration

“This calibration is traceable to the International System of Units (SI) through National Metrology Institutes, ratiometric techniques, or natural physical constants.”

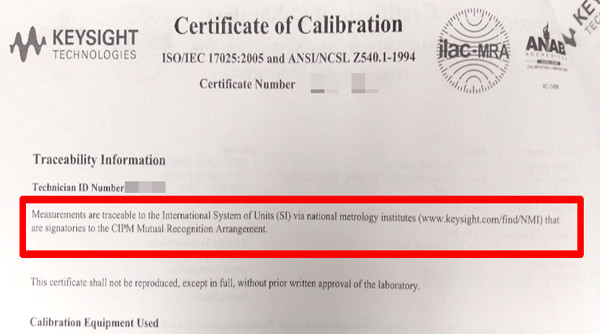

KEYSIGHT Technologies

“Measurements are traceable to the International System of Units via national metrology institutes that are signatories to the CIPM Mutual Recognition Arrangement.”

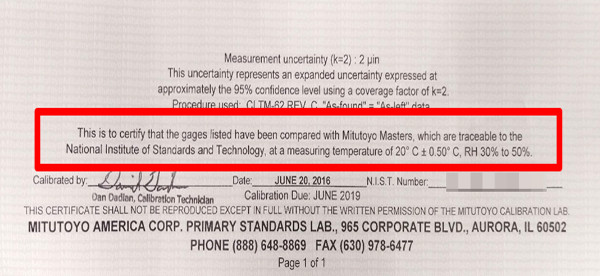

MITUTOYO America Corporation

“This is to certify that the gages listed have been compared with Mitutoyo Masters, which are traceable to the National Institute of Standards and Technology…”

Writing Your Own Traceability Statement

To write your own traceability statement, use the examples above for inspiration. Then, draft your own traceability statement and include it in your calibration reports.

For example;

“The measurement results in this report are traceable to the International System of Units (SI) through the National Institute of Standards and Technology (NIST), or other national metrology institutes.”

NIST Traceable Numbers

For a long time, customers requiring calibration services have requested that NIST Traceable Numbers be included in their calibration and test reports. However, it should be noted that NIST Traceable Numbers are not required, nor recommended, for proof of traceability.

Below is a statement from the NIST Policy on Traceability that explains NIST Traceable Numbers.

“I.B.4 Is a NIST Test Report Number necessary and/or sufficient evidence of traceability?

Test report numbers issued by NIST are intended to be used solely for administrative purposes. Although they are often used to uniquely identify documents which bear evidence of traceability, test report numbers themselves do not address the issues listed in I.B.1 above, and should not be used nor required as the sole proof of traceability.”

Conclusion

Measurement Traceability is an important requirement of ISO/IEC 17025 accreditation. It affects the confidence in your measurement results and the magnitude of your uncertainty estimates.

In this guide, I have provided you a comprehensive explanation on measurement traceability, the requirements of ISO/IEC 17025, and how you can obtain traceability for your measurement results.

Don’t become a victim of the number one cited deficiency in ISO/IEC 17025 audits, obtain measurement traceability via national metrology institutes, accredited calibration laboratories, or certified reference materials. It is your best bet for meeting ISO/IEC 17025 requirements.

If you have any questions related to measurement traceability, leave a comment below.

11 Comments